- Weld Studs & Fasteners

- Capacitor Discharge Equipment

- Drawn Arc Equipment

- Stud Welding Accessories & Consumables

- Stud Welding Automation

- Stud Welding Services

- Drilling, Tapping & Part Manipulation

- Stud Welder Rentals

Weld Studs & Fasteners

At Keystone Fastening Technologies we specialize in creating stud welding and specialty fastening solutions. Let our experts recommend products or engineered solutions for your application.

Capacitor Discharge Equipment

Keystone Capacitor Discharge Stud Welding Systems are Precision Engineered for Long Term Durability and Performance. Our Unique Technology allows operators to achieve Exceptional Weld Quality and Unparalleled Consistency.

Drawn Arc Equipment

Developed for professional use, Keystone Stud Welding Systems effortlessly respond to the toughest workplace demands. Our Proprietary Microprocessor and Current Regulation Technology allows operators to achieve Exceptional Weld Quality and Unparalleled Consistency.

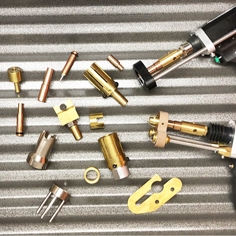

Stud Welding Accessories & Consumables

Keystone Genuine accessories and consumables provided consistent performance and quality every time. Whether for Keystone™ brand equipment or any other stud welding brand, we have your parts.

Stud Welding Automation

Keystone offers a wide range of semi and fully automated stud welding solutions customized to your specific application. Our welding automation provides enhanced weld quality, repeatability and productivity improvements which help reduce your manufacturing costs.

Stud Welding Services

Whether it's manufacturing overflow or the need for precision stud welding services, Keystone can help. Our specialty is offering turn-key production solutions both small and large.

Drilling, Tapping & Part Manipulation

Keystone offers a complete range of high quality, highly efficient Volumec Drilling & Tapping Equipment, Articulating Arms and Part Manipulation Equipment.

Stud Welder Rentals

Keystone Fastening offers a complete line of Stud Welder Rentals both Drawn Arc and Capacitor Discharge.

Rent for a week, a month or whatever timeframe works best for your job.

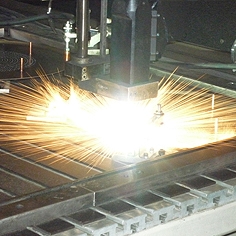

Capacitor Discharge Stud Welding Process

The process utilizes a powerful bank of capacitors to store energy at a specific voltage determined by stud size and material. When a weld is initiated, this energy is "discharged" through a special "ignition tip" at the base of the stud, creating an instantaneous arc which melts both the base of the stud and the adjoining surface on the work piece.

Learn MoreDrawn Arc Stud Welding Process

Drawn-arc stud welding is an extremely efficient method of attaching fasteners primarily to mild steel and stainless steel by utilizing a constant-current DC power supply, typically a 3-phase transformer-rectifier, equipped with integral controls to operate a special drawn-arc stud welding gun.

Learn More